Logistics EDI (Electronic Data Interchange) is a system forexchanging standardized electronic documents between the different actors in the supply chain. It allows companies to automate their processes and make their communication more fluid. They thus reduce their costs and the risk of errors.

The use of systems for the electronic management of commercial, logistics and invoicing documents improves efficiency and performance.

In this article, we will explore the different types of EDI messages used in logistics, as well as the benefits and needs of EDI in this sector.

EDI messages in logistics

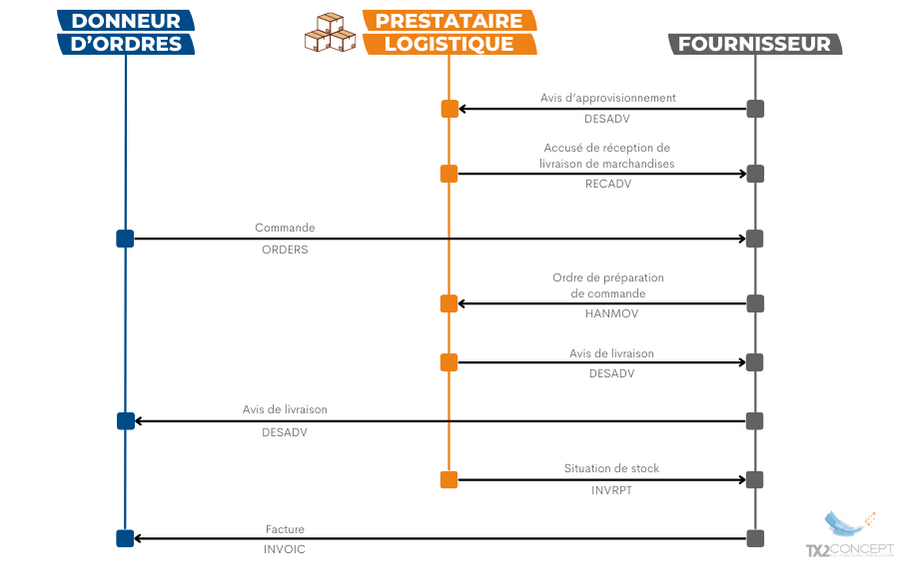

One of the most used standards, particularly in logistics and transport, is EDIFACT. Here are the EDI messages that logisticians and transporters use daily to communicate with their clients or suppliers.

- PARTIN and PRODAT

Exchanged before any order, these messages make it possible to update the database of each partner with information from the logistician, the manufacturer and the goods.

We will have, for example, elements such as the company name, GLN, addresses, product GTINs or even information on packaging.

- Goods’ supply notice: DESADV

When a manufacturer supplies the warehouse stock with goods, he sends an EDI message to his logistician.

To do this, he can inform him via a DESADV, a supply DESADV or an AVA.

- Acknowledgment of goods delivery: RECADV

Once the goods have been transported by the carrier, the logistician acknowledges receipt of the packages with the transmission of a RECADV to its partner.

- Order preparation order: HANMOV

When suppliers receive orders from their clients, they ask their logisticians to prepare these orders so that their carriers can transport them from the warehouse.

To do this, they send an EDI message called HANMOV to request the packages to be shipped.

- Despatch advice: DESADV return

This EDI message is used to inform the supplier that the goods are ready and will be delivered. The supplier can thus invoice its end customer.

- Stock situation: INVRPT

Daily, the logistician sends an INVRPT message to the manufacturer to inform him of the stock situation.

He can thus inform him of the remaining quantities by product and stock movements (number of products delivered, expired, lost, etc.).

Advantages of EDI in logistics

Cost reduction

The automation of processes, the reduction of human errors as well as the reduction of printing and mailings contribute to a reduction in costs.

Improved communication

EDI makes it possible to ease the exchange of up-to-date and complete information between different stakeholders. This also promotes better traceability of information.

Time saving

Direct integration of flows into the ERP, TMS or WMS of all partners allows processes to be accelerated and order processing times to be reduced.

As a reminder, TMS stands for Transport Management System and WMS stands for Warehouse Management System. These are information systems dedicated to transport and logistics companies.

Improved client satisfaction

All these advantages allow better responsiveness to client requests and a reduction in the risk of errors which will promote relationships with your partners.

By using a SaaS or in-station EDI, you improve the efficiency of the entire supply chain. You gain in productivity and performance.

This type of software allows the transmission of your commercial and logistical documents in the format expected by your client. You are thus able to adapt to the demands of your various partners.

EDI needs in logistics

EDI meets a multitude of business needs specific to logistics. It makes it possible to optimize the management of information flows throughout the supply chain.

An EDI solution makes it possible to send stock movements and statuses in real time, process order preparation requests, as well as manage requests for logistics and transport services. This automation of exchanges makes communication more fluid between the different stakeholders, reduces manual errors and optimizes processing times.

This type of software allows you to exchange order tracking information, send shipping notices, and track delivery statuses. This increased traceability allows for better coordination between partners and therefore, better customer satisfaction.

EDI also makes it possible to digitize invoices for more efficient accounting and compliance with tax obligations. The dematerialization of data is secure, guaranteeing the reliability and confidentiality of exchanges.

In summary, EDI meets the specific needs of logistics by automating exchanges, improving traceability and collaboration, and guaranteeing data security.

Conclusion: TX2 Concept and logistics EDI

EDI is a powerful tool to make the supply chain more fluid and to improve logistics performance.

As an EDI expert for more than 30 years, TX2 Concept perfectly masters the constraints specific to this sector of activity. We offer a range of EDI solutions adapted to their needs:

- EDI in SaaS or in station integrated into your ERP, TMS or WMS

- Electronic invoicing, GS1 France certified, positioned as future PDP

Our “business” experts support you at every stage of your project.

We are able to manage a large number of sectoral standards and formats: EDIFACT, Odette/VDA, Tradacom, ANSI X12, XML (UBL, CII, etc.) Factur-X, SAP IDOC… Thanks to our solutions, your company is able to send its data in the format and standard expected by your partner..

If you would like to know more about logistics EDI and our offers, do not hesitate to contact one of our experts.